While the benefits of washing machines are undeniable, many users experience vibrations during operation. This issue is not only annoying but can also impact the efficiency and longevity of the appliance. So, what causes this problem, and how can it be resolved?

There are five common mistakes that households make when using washing machines, which can lead to excessive vibrations and loud noises:

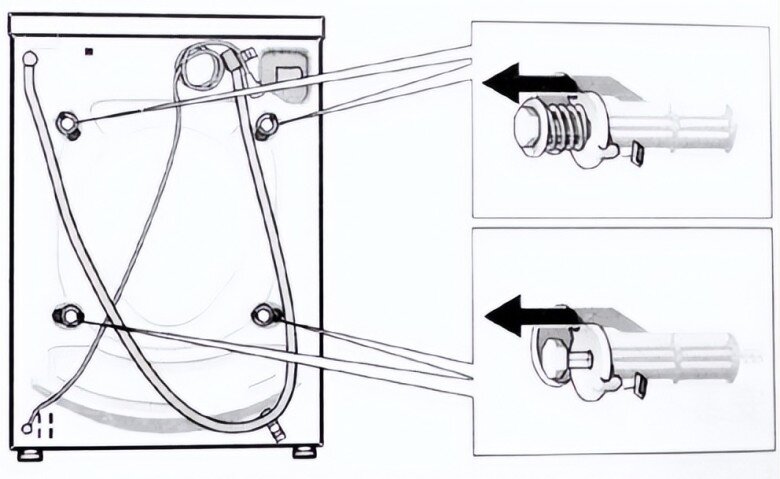

1. Transport Bolts Not Removed

Manufacturers often install transport bolts at the back of washing machines to secure the drum during transportation. If these bolts are not removed before use, the drum won’t spin freely, resulting in intense vibrations.

To fix this, users should immediately remove the bolts with a wrench, usually identified by a plastic cap. After removal, run an empty water-draining cycle to test stability. This step is crucial to ensure the machine operates normally.

2. Unstable Position

One of the most common causes of vibrations is an unstable washing machine position. Uneven flooring or improperly adjusted legs can shift the center of gravity. Statistics show that about 60% of vibration issues stem from this problem.

To address this, users should use a spirit level to balance the legs of the machine. If the floor is uneven, use anti-vibration pads or cardboard to stabilize the appliance. This not only reduces vibrations but also prolongs the machine’s lifespan.

3. Uneven Distribution of Laundry

During washing, unevenly distributed laundry within the drum can also cause vibrations. If too much laundry is loaded on one side or large items like down jackets are not folded properly, the drum will spin out of balance.

To prevent this, users should avoid tightly packing laundry and leave some space between items. For bulky items, fold them into squares before loading. This ensures smoother operation and effective cleaning.

4. Insufficient Clearance

Another overlooked cause is limited clearance around the washing machine. If the gaps on the sides or above the machine are too narrow, it may hit the cabinet during operation, creating a “resonance” effect.

The solution is to maintain standard clearances: at least 5 cm on both sides and more than 10 cm above. This allows for proper ventilation and easy maintenance. Additionally, ensure the cabinet’s stability to reduce vibrations and minimize their impact on the washing machine.

5. Clogged Drainage System

Lastly, a clogged drainage system is a significant contributor to vibrations. If the drain hose is bent, blocked, or improperly connected to the floor drain, wastewater will not discharge effectively during the spin cycle, upsetting the balance of the tub.

To resolve this, regularly clean the drain hose, using a wire to clear obstructions like hair and fabric lint. Also, adjust the hose angle to ensure it slopes downward, preventing bends.

In addition to these causes, regular maintenance is vital. Users should clean the inside of the drum, filters, and bottom dust at least every six months to ensure efficient operation.

If these measures don’t work, components like shock absorbers or bearings may be worn and require expert inspection. Typically, about 80% of vibration issues can be resolved through balancing, bolt removal, and laundry distribution adjustments.

How to Fix a Vibrating and Noisy Washing Machine

If you are experiencing strong vibrations and loud noises coming from your washing machine during its operation, it is important to investigate the source of the issue in order to ensure that it does not worsen. As the drum of the machine rotates at a fast speed to effectively eliminate dirt from clothes, anything out of the ordinary could impede the machine’s ability to function optimally.