Green Farm: More than just a fun day out with cows

Prior to the trip, when asked, most of the children replied that they wanted to go to the farm because they had “never seen a dairy cow before”. However, after the experience, not only did they get to see the cows up close, but they also gathered a lot of interesting information about the daily activities of an eco-friendly farm in a vivid and engaging way.

The tour group, consisting of over 60 students and parents, spent a day at the Vinamilk farm in Tay Ninh, home to a herd of almost 8,000 dairy cows. “Before coming here, I thought the farm would be very hot and sunny. However, as soon as I entered the gate, the first thing that caught my eye was the large lake and the vast green space. The atmosphere at the farm was very mild and pleasant, completely different from what I had initially imagined”, said Hoang Diep, one of the accompanying parents.

During the trip, the calf care area was where the group spent the most time. Nguyen Thanh Bao Duy (Ho Chi Minh City) shared: “When I came here, I was amazed at how beautiful the farm was, with things I never expected like a large lake for temperature regulation and cooling fans. The calves also had modern chips… I was surprised to see so many smart technologies being applied”.

Le Vinh Bao (9 years old, from Ho Chi Minh City), a robot enthusiast, was fascinated by the Lely robot in the dairy cow barn: “I was very impressed by the farm because the cows are well taken care of, especially with the Lely robot feeding them. The robot is programmed to feed the cows on time and with the right amount of food, and it even plays music to relax the cows during mealtimes. The Vinamilk staff also monitor the cows’ health through an app on their phones”.

By learning about the farm’s operations, the children developed a deeper understanding of how technology can be applied to protect the environment. For example, the milk for the calves is heated (pasteurized) using heat generated by the biogas system that treats the dairy cows’ waste and converts it into methane gas. This helps the farm manage cow waste while saving electricity and gas… thereby reducing greenhouse gas emissions.

The children also learned other interesting facts, such as: 100% of renewable resources at Vinamilk farms are equivalent to the amount of electricity used for two round trips from Earth to the Moon, the number of blocks of water for 86 Olympic-sized swimming pools, and the amount of carbon neutralized is equivalent to 30,000 football fields full of trees… Thanks to these efforts, Vinamilk’s fresh milk boxes produced at these farms and factories have less impact on the environment.

The “green” Mega factory welcomes young talents

The Mega factory impressed the students not only with its massive scale, capable of producing 10-12 million boxes of milk per day, but also with its modern technologies, high automation, and use of green energy to reduce emissions.

“I was truly surprised by the students’ very insightful questions about technology, robots, and management systems. Moreover, even though they are only 13-15 years old, they showed a strong interest in environmental protection. I believe they are talents for the future, contributing to the development of more green factories in Vietnam”, shared Tran Minh Tri, Production Supervisor at the Vietnam Dairy Factory (Binh Duong) after meeting with the student group.

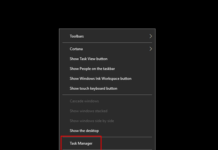

The students listened attentively and took detailed notes on the production process of making a box of milk at the Mega factory: from the giant milk tanks to the packaging line that produces 6-7 boxes of milk per second, and the smart warehouse that handles over 27,000 shipments with computer control…

The entire production and packaging process is automated, programmed, and monitored via a computer system. Notably, the line can detect and reject boxes that do not meet the specified standards before they are packed into the finished product crates.

Not only were the students impressed by the operation of the smart warehouse, but they were also particularly interested in the information that this model can help reduce CO2 emissions by 70% compared to traditional warehouses. Vinamilk currently has 5 such smart warehouses in its factories, including cold storage for products such as yogurt and Probi that require stable cold storage.

Nguyen Thanh Gia Bao (9th grade, Ngo Quyen Secondary School, Hai Phong) shared his impression of the LGV robots in the factory, which can calculate the fastest route to save energy and reduce CO2 emissions by 62% compared to traditional forklifts. “The robots operate very accurately, without any unnecessary movements or mistakes, and they also save energy and reduce emissions. Seeing the robots in action in the factory really inspired me to pursue my passion for creating and programming robots that protect the environment in future competitions”, said Gia Bao.