1. Copper Pipes for Air Conditioners

Copper pipes are an essential component of air conditioning systems, serving as gas conduits that facilitate the flow of gas between the evaporator and condenser. As such, they play a critical role in the cooling process and the overall longevity of the unit. The size and cost of these copper pipes vary depending on the air conditioner’s capacity and the specific application.

Copper pipes facilitate the flow of gas between the evaporator and condenser, ensuring efficient cooling.

2. Why is a Minimum Copper Pipe Length of 3 Meters Recommended?

A copper pipe length of less than 3 meters can cause the air conditioner’s gas to circulate through the block too quickly, resulting in unevaporated gas returning to the block. This overworks the block, leading to overload and potential reduction in the unit’s lifespan. Additionally, shorter pipe lengths can result in increased noise levels due to the continuous and intense vibration of the block during operation, causing disruptions to those nearby.

Copper pipe lengths shorter than 3 meters can lead to overworking of the air conditioner’s components.

3. Optimal Copper Pipe Length for Air Conditioners

The optimal copper pipe length for air conditioners typically ranges from 3 to 7 meters, with a minimum of 3 meters and a maximum of 15 to 20 meters for higher capacity units. Installing pipes shorter than the recommended length can cause gas to become trapped and blocked, leading to malfunctions. Conversely, pipes that are too long can result in reduced cooling efficiency or even the inability to cool at all. Deviating from the manufacturer’s specified length guidelines may also void the warranty.

The optimal copper pipe length for air conditioners ranges from 3 to 7 meters, with maximum lengths reaching 15 to 20 meters for higher capacity units.

4. Additional Standards for Installing Copper Pipes in Air Conditioners

Copper Pipe Sizing

There are two main types of copper pipes used in air conditioners: the pipe from the condenser to the evaporator (suction line) and the pipe from the evaporator to the condenser (discharge line). The suction line has a smaller diameter than the discharge line.

- For a 1 HP (~9000 BTU) air conditioner: The suction line has an outer diameter of 6mm, while the discharge line is 10mm.

- For a 1.5 HP (~12000 BTU) air conditioner: The suction line has an outer diameter of 6mm, and the discharge line is either 10mm or 12mm.

- For a 2 HP (~18000 BTU) air conditioner: The suction line has an outer diameter of 6mm, and the discharge line is 12mm.

- For a 2.5 HP (~24000 BTU) air conditioner: The suction line has an outer diameter of 6mm, and the discharge line is 16mm.

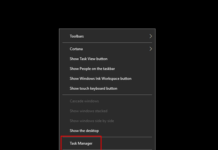

You can also find the recommended pipe sizes in the technical specifications provided by the manufacturer on the product page, as shown in the image below. This will ensure you select the most suitable copper pipes for your air conditioner.

Height Difference Between the Condenser and Evaporator

In addition to the length of the copper pipes, it’s important to consider the height difference between the condenser and evaporator. This should be within the manufacturer’s specified limits and will depend on the length of the copper pipe used. While this factor may not be as significant for installations on the same floor, it becomes crucial for multi-story buildings, high-rises, and apartments.

The height difference between the condenser and evaporator is an important consideration, especially in multi-story buildings.