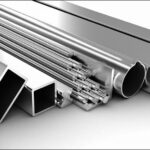

Stainless Steel, or Stainless for short, is a metal alloy made up of various elements such as Nickel, Chromium, Copper, Iron, Carbon, Manganese, and Silicon, among others. This material is known for its high durability, corrosion resistance, and ability to retain its color, making it an excellent choice for manufacturing everyday household items.

The durability of stainless steel depends on the mixture of alloys such as Chromium and Carbon. A higher Chromium content in the steel results in better oxidation resistance. The most common types of stainless steel used today are 201, 304, 316, 301, and 430.

Characteristics of Stainless Steel

The characteristics of stainless steel can be categorized into four main groups, each with several subdivisions:

- Austenitic: SUS 301, 304, 304L, 316, 316L, 321, and 310s, among others.

- Ferritic: SUS 409, 410, and 430.

- Austenitic-Ferritic (Duplex): LDX 2101, SAF 2304, 2205, and 253MA.

- Martensitic: 420S45 and 248SV.

In general, the characteristics of stainless steel include the following:

| Alloy Group | Magnetism | Corrosion Resistance | Ductility | Heat Resistance |

| Austenitic | No | High | Very High | Very High |

| Duplex | Yes | Very High | Medium | Low |

| Ferritic | Yes | Medium | Medium | High |

| Martensitic | Yes | Medium | Low | Low |

| Phase Stabilized | Yes | Medium | Medium | Low |

Common Types of Stainless Steel

Comparing Common Types of Stainless Steel

Stainless Steel 304

Stainless Steel 201

Stainless Steel 316

Stainless Steel 430

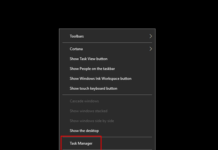

How to Distinguish Common Types of Stainless Steel

Using Acid

Using Specialized Testing Solutions

Using Toilet Bowl Cleaner

Using a Magnet

Frequently Asked Questions About Stainless Steel

What is Stainless Steel?

What is Stainless Steel, and How is it Used in Manufacturing?

Stainless steel is an iron alloy containing at least 10.5% chromium, known for its corrosion resistance and ability to withstand corrosive environments. In manufacturing, stainless steel is used to produce household goods, medical equipment, food industry applications, and more.

Why Doesn’t Stainless Steel Rust?

Chromium in stainless steel forms an oxide layer on the surface, preventing the iron inside from corroding.

How is Stainless Steel Fabricated?

Stainless steel can be fabricated through cutting, grinding, bending, welding, and polishing processes to create finished products.

What are the Main Forms of Stainless Steel Used in Manufacturing?

Stainless steel is commonly used to produce tubes, sheets, bars, wires, and household items such as showerheads and sinks.

How is a Smooth and Shiny Surface Created on Stainless Steel?

A shiny surface on stainless steel can be achieved through polishing and chromium plating processes.

Can Stainless Steel Withstand High Temperatures?

Yes, stainless steel has excellent heat resistance and is used in industries such as chemical and metallurgical engineering.

How is Stainless Steel Used in the Food Industry?

Stainless steel is used for food storage, cooking pots, water pipes, and various other applications in the food industry due to its safety and optimal characteristics.

Does Stainless Steel Have High Durability?

Yes, stainless steel has high durability, corrosion resistance, and chemical resistance, ensuring that products maintain their structural integrity and appearance over the long term.

How Should Stainless Steel Products be Stored and Cleaned?

Stainless steel products can be cleaned with warm water and soap. For storage, avoid corrosive chemicals and keep them in a dry place.

What Forms Does Stainless Steel Take in Mechanical Engineering?

Stainless steel can be formed into round or square tubes, solid bars, sheets, and various other shapes depending on the application in mechanical engineering.

Why is Stainless Steel a Good Choice for Medical Device Manufacturing?

Stainless steel is ideal for medical devices and surgical instruments due to its corrosion resistance, ease of cleaning, and durability.

How is Stainless Steel Welded?

Stainless steel welding requires TIG or MIG welding technology to prevent surface rust.

Does Stainless Steel Have Good Durability in Seawater Environments?

Yes, stainless steel has excellent corrosion resistance in seawater and is commonly used in shipbuilding and marine structures.

Why is Stainless Steel Called “Stainless”?

The name “stainless” comes from the French word “inoxydable,” meaning “not oxidizable,” referring to the steel’s corrosion resistance.

Can Stainless Steel be Recycled?

Yes, stainless steel can be recycled and reused to produce new products.

What are the Common Alloys of Stainless Steel?

SUS 304 and SUS 316 are common alloys, with chromium and nickel as their main components.

Is Stainless Steel Used in Renewable Energy Applications?

Yes, stainless steel is used in the production of components for renewable energy systems, such as solar and wind power.

Does Stainless Steel Have Any Disadvantages?

Stainless steel is generally more expensive than other types of steel and requires specialized fabrication techniques.

Is Stainless Steel Used in the Aerospace Industry?

Yes, stainless steel is used in aircraft and spacecraft manufacturing due to its durability and heat resistance.

What Advantages Does Stainless Steel Offer Over Other Materials in Manufacturing?

Stainless steel stands out for its corrosion resistance, chemical resistance, and aesthetic appeal, making it a preferred choice for various manufacturing applications.

With over 15 years of experience in web design and development, I am an expert in creating comprehensive web development plans for businesses. My goal is to help companies develop sustainable and profitable websites.

What is Stainless Steel? How to Distinguish Common Types of Stainless Steel.

Introducing Inox – the versatile material of choice for a myriad of applications. With its superior qualities, Inox has become a household name, renowned for its durability and sleek aesthetic. Crafted from the finest materials and designed to perfection, Inox delivers an unparalleled experience, ensuring longevity and style in equal measure.

Why Are More People Opting for Bare Walls Instead of Tiles? Avoid the 3-Year Regret.

Once a popular trend, wall-tile flooring has now fallen out of favor with many homeowners. But why has this once-loved design feature landed on the ‘blacklist’ for some?

[Continue with the article, providing an insightful exploration into the rise and potential fall of wall-tile flooring, perhaps delving into the aesthetics, functionality, and maintenance of this controversial design choice.]